We are progressing towards electric vehicles and vehicles powered by alternative fuels today, but let’s not forget the internal combustion engine served as the centerpiece of automobile innovation.

When we talk about cars, the first thing that comes to our mind is the car engine. It’s important to know that the engine is made of many parts of machinery. Other than the fuel, all other required features are housed within the vehicle itself.

With the basic knowledge of the different parts of a car engine and their functions, it becomes possible to readily determine the problem affecting the vehicle and take the necessary steps to fix it. So, let’s take a look at how a car engine works.

How Does a Car Engine Work?

More precisely, an internal-combustion engine is a type of heat engine, as it transforms the energy from the burning of gasoline into mechanical work, or torque. That torque turns the wheels, which propels the car forward.

Your engine operates on the same basic principles whether you’re driving a Ford or a Ferrari, except if you’re driving an ancient two-stroke Saab (which sounds like an old chainsaw belching oily smoke out its exhaust).

Every engine has pistons that go up and down within hollow metal tubes called cylinders. Picture riding a bicycle, your legs go up and down as if to turn the pedals.

Pistons are connected via rods (which are your shins) to a crankshaft, and they move up and down to spin the engine’s crankshaft, which is the same as your legs powering the bike’s drive wheel or the car’s.

Whichever vehicle it may be, an engine usually contains from two to twelve of these cylinders. Each has a piston that goes up and down in a cylinder.

Where Does Engine Power Come From?

The power behind the pistons is usually a series of controlled explosions that happen every minute, known as combustion, or the power stroke. Each stroke releases heat and expanding gas from an ignition, a mini-explosion, that moves the piston further down into the cylinder.

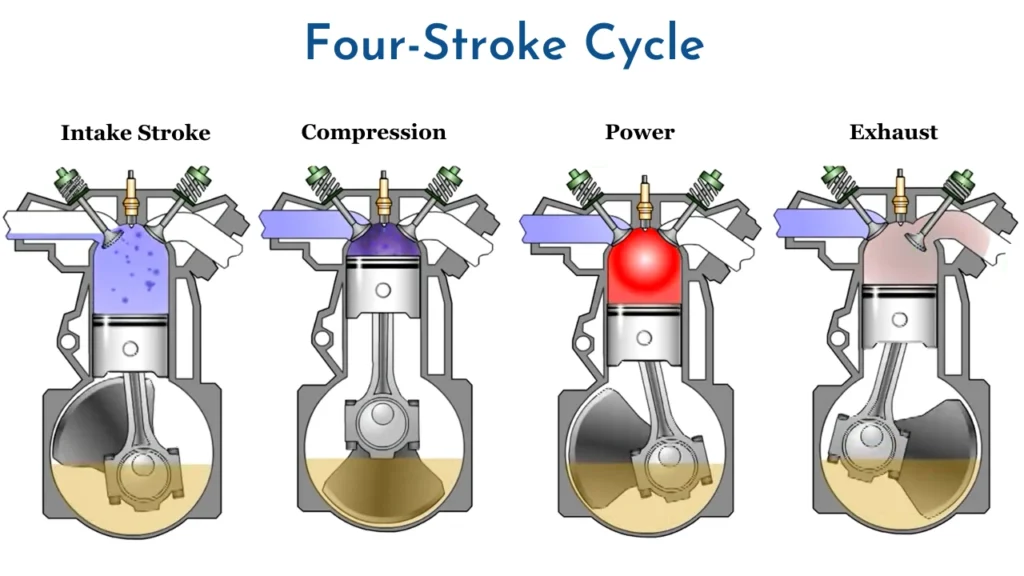

In today’s world, almost all internal combustion engines utilize the four-stroke system. For simplicity’s sake, we’ll only discuss gasoline engines. In addition to the combustion stroke, which propels the piston from the top of the cylinder, there are three other strokes: intake, compression, and exhaust.

A fuel-burning engine requires air and particularly oxygen. As for the intake stroke, it is the stage when valves open allowing the piston to perform a syringe-like motion sucking in air from the atmosphere through the engine’s intake system.

During the piston’s stroke, the intake valves obstruct the passage which in turn seals the cylinder for a compression stroke. This needs to happen in contrast to the direction of the intake stroke. The piston’s upward movement compresses the intake charge.

The Four Strokes of a Four-Stroke Engine

In modern combustion engines, fuel is injected into the cylinder near the compression stroke. In some others, there is an ‘intake’ and a ‘premixing’ stage.

Like during the intake stroke, the air and fuel are mingled before entering the combustion chamber. In both instances, air and fuel are mixed and then sparked, which is called ignition. It is triggered as the piston approaches the peak height of its upward vertical motion.

The piston is propelled downwards, or rather along the axis of the cylinder, toward the crankshaft, as the fuel burns in the combustion chamber and transforms the expanding gas’s outcome.

The wheels of vehicles like cars can be rotated via this stroke, aka the combustion stroke. Even cycling has a similar working mechanism, – pedaling makes a bike’s wheels rotate in the same way.

The upper and lower extremes of a cylinder are referred to as ‘top dead center’ (TDC) and ‘bottom dead center’ (BDC). When BDC is achieved, exhaust valves open and allow the gases from combustion to be removed from the engine. The piston is again enabled to start moving upwards like a syringe that pumps air, which gets removed from a canister.

The expelled exhaust flows through the car exhaust system and out of the rear. The exhaust valves are closed at top dead center allowing the cycle to repeat.

For a multicylinder car engine, combustion strokes happen in cycles, and offset happens in such a way that causes the engine to be smooth and well balanced. This is done to prevent simultaneous combustion strokes from happening in one cylinder and at the same time provide balance to the engine for smooth operation.

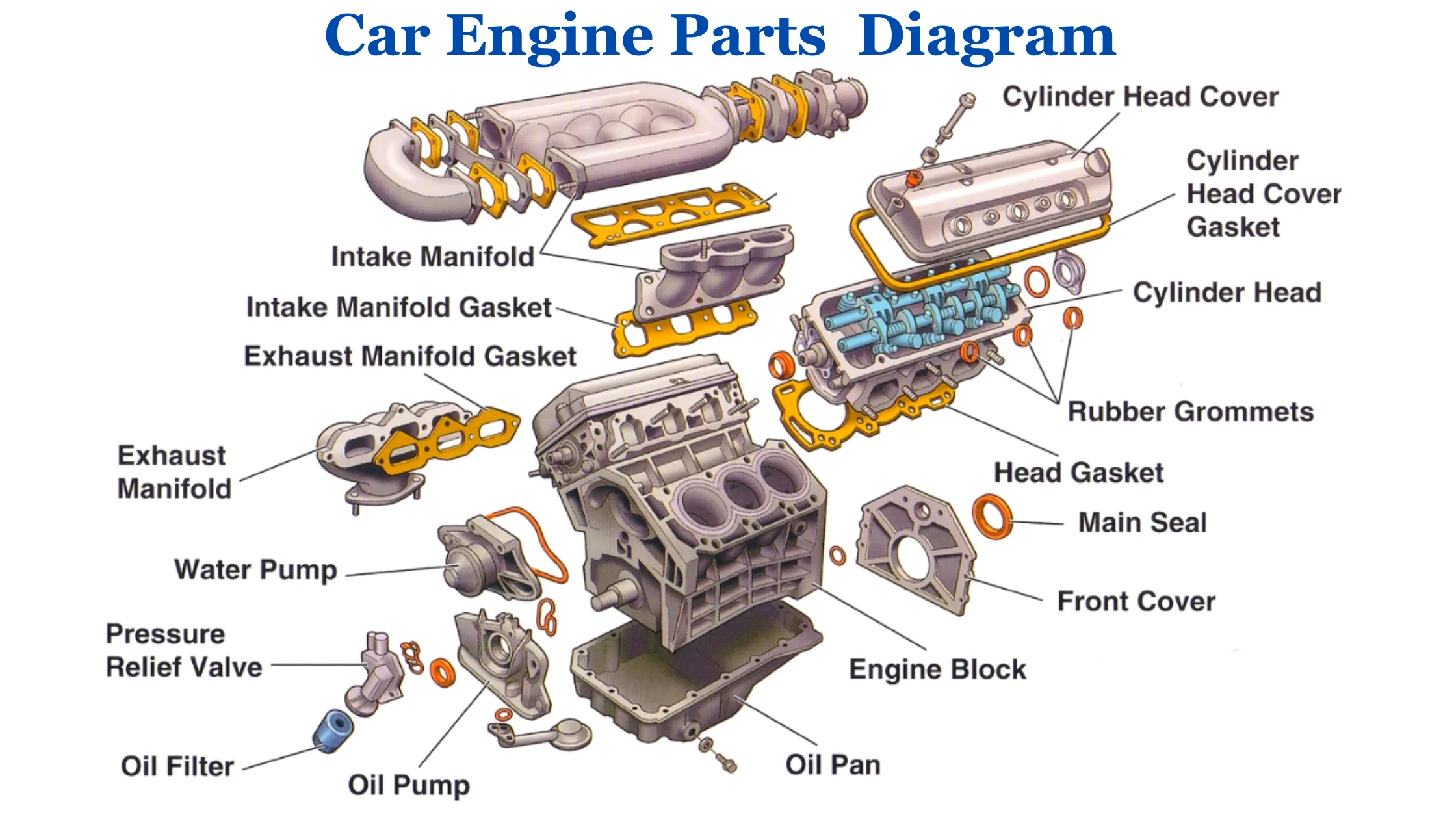

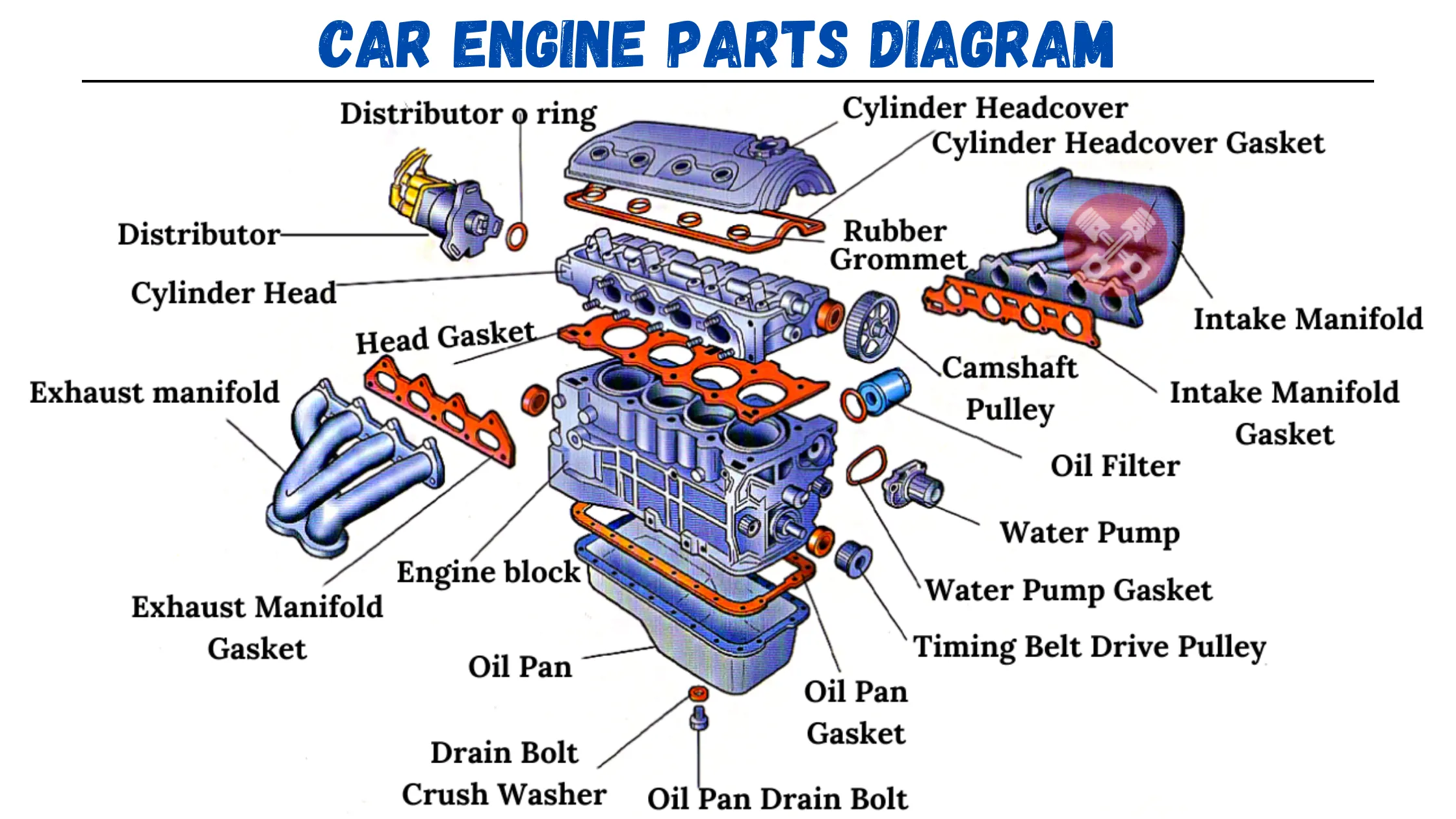

Car Engine Parts Names with Diagram

Let us see a simple car engine parts diagram including all the main parts which are essential to know. Refer to the below car engine parts diagram so that we can understand the exact location of each one and how it looks.

These diagrams typically include the engine block, combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valves, rocker arms, pushrods/lifters, injectors, spark plugs, oil pan, distributor, connecting rods, piston ring, flywheels.

List Of Car Engine Parts Names

While many of us think of the engine as one major component, it’s made up of several individual components working simultaneously.

The list of Car Engine parts Name:

- Engine block

- Piston

- Cylinder Head

- Crankshaft

- Camshaft

- Timing belt

- Engine Valves

- Oil Pan

- Combustion chamber

- Intake manifold

- Exhaust manifold

- Spark Plugs

- Connecting Rod

- Piston Ring

- Gudgeon pin

- Cam

- Flywheels

- Head gasket

- Crank Case

- Cylinder Liner

- Distributor

- Distributor o ring

- Cylinder headcover

- Rubber grommet

- Camshaft pulley

- Oil filter

- Water pump

- Timing belt drive pulley

- Oil pan drain bolt

- Turbocharger and supercharger

- Starter motor

A typical internal combustion engine has around 200 parts that need to be maintained and possibly replaced if they wear out. An electric vehicle takes that number down to around 20 parts.

But don’t worry, we are only discussing the main parts of a car engine.

Read more: 50 Basic Parts of a Car With Name & Diagram

Parts of A Car Engine

The different parts that make up your car’s engine consist of: the engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valve train, valves, rocker’s arms, pushrods/lifters, fuel injectors, and spark plugs.

#1. Engine Block.

The engine block is the very base of the entire engine and is usually composed of either aluminum or iron. The engine block contains several holes for the cylinders, and the structure contains water and oil pathways to cool and lubricate the engine. Narrower Oil paths outsource the larger water flow paths.

In addition, the engine block contains the pistons, crankshaft, camshaft, and depending on the vehicle, four to twelve cylinders which are arranged in a line, inline, flat or in a V position.

#2. Pistons.

They have the shape of cylinder with a flat tip. In order to move the vehicle, the piston needs to transmit the energy as a result of combustion to the crankshaft. During each rotation of the crankshaft, the pistons are up and down within the cylinder two times.

At 1250 RPM, the pistons in the engine will complete 2500 cycles of up and down movements per minute. Each piston has an internal piston ring system that aids compression and reduces friction on the cylinder due to constant rubbing.

#3. Piston Rings.

Piston rings are a type of rotatable seal fitted around the piston to allow the piston to move freely to and from the cylinder wall while providing a seal.

They stop combustion gases from escaping the combustion chamber and aid oil distribution on the cylinder walls for lubrication purposes.

#4. Connecting Rods.

The connecting rods are responsible for linking the piston to the crankshaft. They also have an important function of converting the pistons’ upward and downward movements to crankshaft rotational movement, which is needed to rotate the wheels.

#5. Crankshaft.

The crankshaft is the lower part of the engine block and, sits on the crankshaft journals which is an area of the shaft on the bearings. The pistons are connected to this tightly machined and balanced mechanism via a connecting rod.

The piston movement is similar to a jack-in-the-box: the upward and downward movement of the piston is turned into reciprocal motion at engine speed by the crankshaft.

#6. Camshaft.

Depending on the make and model of the vehicle, the camshaft may be in the engine block or in the cylinder heads. Most contemporary automobiles possess them in the heads, considered dual and single overhead camshaft (DOHC/SOHC) systems, and are held in place by a series of oil-saturated bearings for extended lifespan.

The camshaft’s job is to manage the timong of the opening and closing of valves, taking rotary motion from the crankshaft and converting it to an up-and-down motion that controls the lifters and subsequently movements in the pushrod, rockers, and valves.

#7. Cylinder Head.

Along with a set of bolts to the engine’s block, the cylinder head is attached and sealed by a head gasket.

The assembly features a range of components including valve spring, valves, lifters, pushrods, rockers and camshafts as well as passageways for the inflow of fresh air into the cylinders during the intake stroke and outflow of spent air during the exhaust stroke.

#8. Combustion Chamber.

In an engine, the combustion chamber plays a crucial role. The area where an explosion occurs and fuel, electricity, and air combine to give power to the pistons of the motor that makes the car move is called the combustion chamber.

The combustion chamber includes the piston, cylinder, and cylinder head. The entire structure forms the combustion chamber. The cylinder works as the wall, the piston top acts like a floor, and the cylinder head serves as the top of the combustion chamber.

#9. Timing Belt/Chain.

The timing of camshaft and crankshaft rotation is crucial. They must be, in a 1 to 1 ratio, to keep the engine working. A rugged rubber belt with cogs is used on camshaft and crankshaft pulleys. A tooth bicycle-like chain goes around the sprocket.

#10. Spark Plugs.

An air-fuel mixture combustion chamber needs a spark for ignition to ensure smooth functioning. Gasoline is used as fuel for Spark Ignition Engines (SIE). The air-fuel mixture has to be ignited at the right time, and no other for it to serve its purpose.

It commences a controlled series of detonations within the engine to create the power required to operate your vehicle. An internal combustion engine has a spark plug, which ignites fuel and air into an explosion.

The engine draws power as long as the internal combustion spark plug remains good and generates appropriate power. Over longer periods of time, achieving milestones such as 60,000 miles, spark plugs will require this replacement on average.

Vehicles with more demanding performance or heavy usage will require more frequent spark plug checks and replacements. Each car maintenance owner manual specifies the precise intervals for checks and replacements of other vehicle parts.

But keep in mind that you cannot service spark plugs, as the only tasks to be performed are removing or replacing them. Leaving replacements unattended will eventually lead to fuel waste, reduced vehicle productivity, fuel wastage, and situations of rattling idle around the vehicle.

#11. Flywheel.

Coupled to the crankshaft, the circular flywheel acts as supplemental storage of rotational energy stemming from the engines combustion. The goal, or rather, flywheel’s responsibility is to store and release energy.

For starters, delivering a smoother idle along with reducing the idling speed of the engine. The torque converter housing, next to the clutch of the flywheel, is often mated on calibration scope along the flywheel.

#12. Valves.

There are two types of valves in a vehicle: intake valves and outlet valves. Intake valves bring air and fuel into the combustion chamber to create an explosion that powers the engine. Outlet valves allow for waste and exhaust that is produced from combustion to escape the combustion chamber.

Posh vehicles like Jaguars and Maseratis are equipped with one intake and one outlet valve in each cylinder, totaling up to four valves per cylinder – two intake and two outlet. As a brand not often referred to as “high performance,” Honda also employs four valves per cylinder.

Some engines contain three valves per cylinder, and two of them are inlet valves with an outlet valve. The car is better able to “breathe,” allowing for increased engine performance due to multi-valve systems.

#13. Valvetrain.

A part of a car engine that makes up the valvetrain consists of valves, camshafts, and other parts that open and close the valves in relation to the engine’s operation.

As fuel gets injected within the cylinder, through the intake valve that was previously turned on, the exhaust valve opens to let out the byproducts resulting from combustion.

#14. Rocker Arms.

Rocker arms are small levers that come in contact with the lobes, or cam, of the camshaft. When a lobe rises to lift one side of the rocker arm, the other side of the rocker arm rotates, depressing the valve stem and opening the valve so that air can flow into the combustion chamber or exhaust can flow out. It functions similarly to a see-saw.

#15. Pushrods/Lifters.

In some engine designs, a rocker arm is connected to a valve via a shaft and link, so that the camshaft lobes can directly actuate the rocker arm (as seen in overhead camshaft engines). In other configurations, like overhead valve engines, there is no direct line of motion between the cam shaft lobes and the rocker arms; therefore, a pushrod or lifter is necessary.

#16. Air Intake System.

The air intake system cleans and supplies air to the engine. It incorporates an air filter that gets rid of contaminants, as well as ducts or tubes that funnel the air into the intake manifold.

A throttle body modulates the volume of air supplied to the engine, enhancing or downgrading its performance.

#17. Fuel Delivery System.

The fuel delivery system is a device that guarantees the engine gets the correct volume of fuel to blend with the incoming air. Like any other device, their system comprises certain parts, including fuel pumps and injectors, as well as the fuel tank.

Fuel injectors atomize fuel and inject it into the manifold, where it is transformed into gas and mixed with air. Likewise, this compound is compressed in the cylinder before burning.

#18. Throttle Body.

The throttle body’s responsibility is to ensure that a proper amount of air enters the engine. It adjusts the size of the opening so that it corresponds to what the driver inputs, and thus controls the Engine Power and RPMs.

#19. Fuel Injectors.

They perform the function of injecting fuel into the intake manifold and are electronically controlled injectors that pulse, releasing fuel in correspondence with the airflow, to provide an exact mixture of oxygen and fuel.

#20. Intake Manifold.

The system is made of a set of tubes or passages, and their purpose is to transport the mixture of air and fuel out, as well as distribute it to the cylinders. It also enhances the movement of the mixture, which is considered for the level of performance of the engine.

#21. Exhaust Manifold.

The exhaust manifold integrates all exhausts into one pipe which results in exhausts from multiple cylinders being collected into one pipe. It has a port for each cylinder, and is connected to the cylinder heads with gaskets.

The catalytic converter is the second part of the exhaust system. The exhaust manifold takes the place of the first part of the exhaust system, and takes the exhaust gases that are released by the engine cylinders and delivers them to the catalytic converter.

Generally, turbocharged engines have the turbocharger fixed behind the exhaust manifold. They are mainly constructed using tubular steel, stainless steel or iron.

Exhaust manifolds also serve the purpose of removing the gases released during combustion. The exhaust manifold must collect unburned fuel, which exposes the manifold to exceptionally high temperatures, vaporizing any remnants of fuel.

The manifold also houses the oxygen sensor in your exhaust system to check the amount of oxygen entering the system.

#22. Head Gasket.

The two main parts of a car engine is its block which contains the pistons and cylinders, and the cylinder head which has various additional components, valves, and spark plugs.

With the rest of the engine rotating the crank shaft, there’s smooth harmonic power transfer, the head gasket works as a prominent component. It allows transferring burning gases in the selected passage while sealing the other passage.

The purpose of the head gasket includes retaining the combustion within the cylinders and preventing coolant or engine oil from entering the cylinders. Damage to the head gasket is likely to result in blow to engine performance.

#23. Lubrication System.

The primary aim of the lubrication system is to minimize friction and wear between moving components.

It utilizes the engine oil, an oil pump, and a series of passages that deliver oil to various parts of the engine to accomplish this task. It is clear that without lubrication, all of the moving parts in an engine would tear each other apart.

#24. Cooling System.

Engines can reach very high temperatures while working, and constantly overheating might cause serious damage. This is prevented by the cooling system, which utilizes a blend of water and coolant to lower the temperature of the engine.

Circulation of the coolant is done by the water pump through the engine and radiator, where heat is radiated into the air. A thermostat is also used to ensure the engine remains at the optimal temperature for efficiency and longevity.

#25. Sump.

The sump also acts as the reservoir for the engine’s oil. It does not wear out too fast and is therefore replaceable every seven to ten years.

The core parts of an engine operate in harmony, transforming fuel and air into motion.

The power is generated by the cylinder block and pistons, while the flow is controlled by the cylinder head and valvetrain. The right balance is achieved by the delivery system that mixes fuel and air, but the lubrication and cooling systems maintain order.

FAQs.

What Is an Engine?

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Most modern vehicles use internal combustion engines (ICE), which ignite the fuel and use the reaction to move mechanical parts.

How Does a Car Engine Work?

The engine consists of a fixed cylinder and a moving piston. The expanding combustion gases push the piston, which in turn rotates the crankshaft. Ultimately, through a system of gears in the powertrain, this motion drives the vehicle’s wheels.

What are the different parts of an engine?

The different parts that make up your car’s engine consist of: the engine block (cylinder block), combustion chamber, cylinder head, pistons, crankshaft, camshaft, timing chain, valve train, valves, rocker’s arms, pushrods/lifters, fuel injectors, and spark plugs.

How many parts are in a car engine?

A common internal combustion engine has around 200 parts that need to be maintained and possibly replaced if they wear out. An electric vehicle takes that number down to around 20 parts.

What Engine Does My Car Have?

You can identify your car’s engine type by the VIN found in the owner’s manual or under the hood. The eighth digit contains the information on the engine.